After three days of working on the house this week, the porch on the front, east side, and back of the house is now ready for the purlins. Yesterday, Danny and I installed the rest of the header beams that were still needed and worked on some of the rafters.

Before Danny came down the hill to help, I put up a header board across the front of the house to attach the porch rafters to. Originally, I thought I was going to attach the rafters on the front to the girts on the front of the timber frame. Previously, we put up the vertical stringers across the front, attaching them to a 2x4 we nailed to the house rafters. In order to attach the porch rafters to the timber frame, I would have to notch each one to fit over the 2x4 at the top of the vertical stringers.

It occurred to me that I could put a header up on the vertical stringers, notching it around the rafters under the metal roof. This actually worked well and was quite easy to do. Once it was up, the rafters, which could be cut to the same length as the rest of them around the house, were fairly easy to put up.

We used the porch rafters to assure that the porch posts were plumb toward the house. We plumbed them the other direction when attaching the headers on Monday.

We used the porch rafters to assure that the porch posts were plumb toward the house. We plumbed them the other direction when attaching the headers on Monday.

After we finished the rafters on the front of the house, we cut the remaining headers to go on top of the posts along the back and the northeast corner. After putting these up,  I laid out the location for the rafters along the back and the east side. We then attached the rafters that were nearest the posts in order to tie them to the house and to make sure they were plumb in that direction.

I laid out the location for the rafters along the back and the east side. We then attached the rafters that were nearest the posts in order to tie them to the house and to make sure they were plumb in that direction.

This morning, I had two posts to plumb and tie to the house with rafters. Once I had those two up, my dad came down to help me. Jon wasn’t able to make it, and Danny had another job to work on.

Before starting on the rafters, I cut several rafters to length out of some of the 2x6s I bought on Sunday. Dad and I worked on getting all the rafters up between the ones already attached near the posts.  Once we had all of these done, we started on the rafters at the northeast corner of the porch.

Once we had all of these done, we started on the rafters at the northeast corner of the porch.

The corners will have a hip roof. I’d previously set aside 2x6s of sufficient length for each corner. I’m doubling the rafters on the corners since they have a greater span and will be carrying more of the roof load than the other rafters.

We figured out the angles we needed and began by putting the first two 2x6s in place.  Each of the rafters we’ve installed for the porch has had to be notched to fit onto the header. I’ve found that it’s easier to use a chisel and hammer for this than it is to use a saw. We would put each rafter into place, mark the outside edge of the header on the bottom of it, take it down, and then cut the notch.

Each of the rafters we’ve installed for the porch has had to be notched to fit onto the header. I’ve found that it’s easier to use a chisel and hammer for this than it is to use a saw. We would put each rafter into place, mark the outside edge of the header on the bottom of it, take it down, and then cut the notch.

For the corner rafters, the notch is cut at an angle.  It wasn’t too hard to chisel it so that it fit tightly while the rafters met up at the corner on the house side. We left these 2x6s long to be cut later after we had the rafters that but into this main one installed.

It wasn’t too hard to chisel it so that it fit tightly while the rafters met up at the corner on the house side. We left these 2x6s long to be cut later after we had the rafters that but into this main one installed.

We measured, cut, and put up the other corner rafters one at a time, notching them as we went. Once they were all up, we snapped a chalk line to mark where they needed to be cut off for the proper overhang.  It didn’t take long to cut them.

It didn’t take long to cut them.

After lunch we worked on the southeast corner rafters. We were able to finish this corner before we quit this evening. We also moved supplies to be ready to get the corner above the root cellar done next.

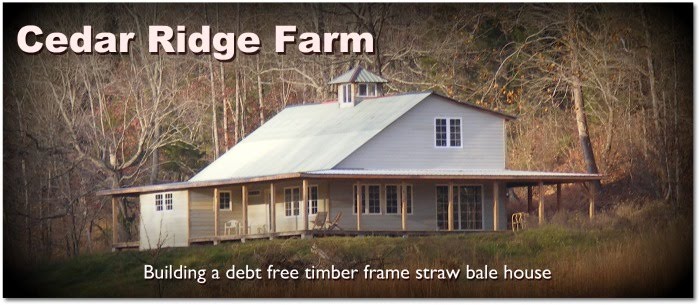

So, the porch rafters along the front, east side, and back of the house are all up. It’s looking good!

times I just had to stand still and enjoy how refreshing the breeze felt.

times I just had to stand still and enjoy how refreshing the breeze felt.

I don’t need or want 4 inches of metal overhanging the edge. The goal is 1.5 inches, an appropriate amount for the gutters that I will eventually install around the porch.

I don’t need or want 4 inches of metal overhanging the edge. The goal is 1.5 inches, an appropriate amount for the gutters that I will eventually install around the porch.