We had some rain early this week. I thought that might slow down work on the house, but we were able to still get things done.

We had some rain early this week. I thought that might slow down work on the house, but we were able to still get things done.

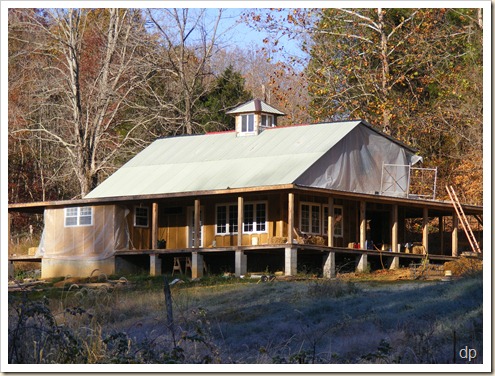

Dad and I worked on the second coat of plaster on the walls under the porch roof – the south, east, and north walls. In two days’ work, we were able to get all the way around except for two small sections above the back door which I’ll finish later.  We ran out of plaster at the end of the day, otherwise these sections would be completed, too.

We ran out of plaster at the end of the day, otherwise these sections would be completed, too.

Working on the second coat on the exterior, I’ve learned a few things which will help when the time comes to plaster the interior. On the inside, I want a nice, fairly smooth and even wall surface. One of the things that I’ve learned is to be sure to prep the wall adequately, filling in voids and generally making the surface to be plastered as smooth and straight as possible.

On the outside there are places in the first coat of plaster which are higher and lower than other sections. The low spots need extra plaster to fill them and the high spots require a greater thickness of plaster over the wall to achieve a smooth, flat surface. On the exterior, since it will have siding, it’s not important to completely smooth out the wall. So, we’ve not endeavored to achieve the same sort of surface which I desire for the inside.

Another lesson I’ve learned is to make sure the plaster mix only has the amount of clay that is needed. An excessive amount of clay in the plaster causes it to crack while it dries since clay shrinks as it dries.  It is amazing how hard the plaster gets when it dries even when it is mixed with only 28% to 30% clay content.

It is amazing how hard the plaster gets when it dries even when it is mixed with only 28% to 30% clay content.

Since we pretty much finished the second coat of plaster downstairs, we went ahead and installed some windows and doors yesterday. We put in the front door, the back door, the living room windows, the master bedroom window, and the two bathroom windows. These went in very well, the biggest time consuming part being cleaning the almost five years of accumulated dust and dirt off of large windows.

We were going to install the small windows that will go above the wood stove, but it has one pane of glass that is cracked which allowed some dirt to get between the panes. We’ve taken the window apart, and I will install a new pane of glass and clean the inside surface of the other pane. Then, I’ll be able to put this window in.

We also didn’t install the large sliding glass door that goes in Anne’s and my bedroom. We’ll do that later. There’s no rush.

We ought to be able to plaster the exterior upstairs walls early this coming week. I’m expecting a few people to come over tomorrow to help with the second coat. Once we have it completed, I’ll install the upstairs windows, at which time they will all be in. Then, there are a few small tasks to complete before starting on the siding.