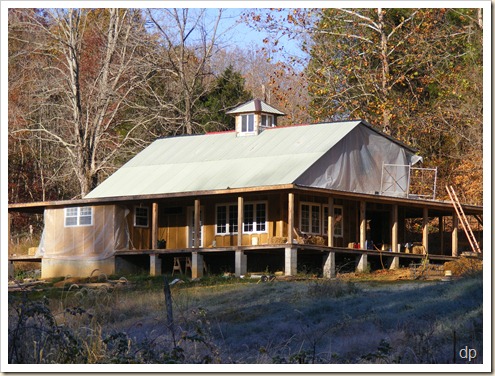

The plaster that was applied on the day of the mud party is drying nicely. It looks like the upstairs walls will be dry by this weekend while the walls under the porch roof will take a few days longer. They don’t get the same air and sunlight, of course.

Danny and I started applying the second coat on Tuesday to some of the walls which we’d previously plastered with the first coat. The walls from the sewing room/study around the laundry room and mudroom all the way to the kitchen had a dry first coat of plaster. It was easiest to start on the porch area on the west side of the house.

Even though we didn’t get an early start and took some extra time in the middle of the day for a couple of errands, we were able to complete all of the wall area on this side of the  porch and begin on the other side of the kitchen.

porch and begin on the other side of the kitchen.

One of the reasons that I selected this wall to start with is because it is protected by the porch roof. I wasn’t sure about the mix ratios for the plaster, and we still needed to figure out how to best apply it. If there are cracks in the plaster here or application problems, they are less likely to cause any problems than if they were elsewhere.

Yesterday, Dad and Jon joined Danny and I in plastering around the rest of the walls that had dry first coat plaster. We were able to get the second coat on all of these areas except for three very small areas on the kitchen walls (there wasn’t enough in the last batch of plaster). I’ll complete these today or tomorrow.

Yesterday, Dad and Jon joined Danny and I in plastering around the rest of the walls that had dry first coat plaster. We were able to get the second coat on all of these areas except for three very small areas on the kitchen walls (there wasn’t enough in the last batch of plaster). I’ll complete these today or tomorrow.

I ended up mixing five gallons of clay with ten gallons of sand, a quart of wheat paste, a gallon of chopped straw, and about  four gallons of water (we chopped the straw with a mulching lawn mower). The application procedure involved wetting the surface of the previous coat of plaster (we used a garden sprayer), smearing plaster on the wall by hand, getting plenty in the corners, edges, and deep spots, and then using a trowel to smooth it out and add more plaster as needed.

four gallons of water (we chopped the straw with a mulching lawn mower). The application procedure involved wetting the surface of the previous coat of plaster (we used a garden sprayer), smearing plaster on the wall by hand, getting plenty in the corners, edges, and deep spots, and then using a trowel to smooth it out and add more plaster as needed.

The ideal is to have a flat, even surface. However, we didn’t pursue that ideal. The operating goal we had was to get a good coat of plaster over the first coat, smoothing out the depressions and ridges as best we could.  We didn’t worry about a smooth, flat surface as much as increasing the overall thickness of the plaster on the wall, filling voids/depressions, generally smoothing out undulations in the wall, and sealing up cracks on the first coat. The resulting surface still has undulations, less than what was there before, though. Since it will be covered with siding, it’s not necessary for it to be perfectly smooth and flat.

We didn’t worry about a smooth, flat surface as much as increasing the overall thickness of the plaster on the wall, filling voids/depressions, generally smoothing out undulations in the wall, and sealing up cracks on the first coat. The resulting surface still has undulations, less than what was there before, though. Since it will be covered with siding, it’s not necessary for it to be perfectly smooth and flat.

As the plaster dries, I will be able to observe the number and types of cracks that appear in the surface. They aren’t critical at this point, and I may or may not do something to seal them, depending on their location and size. The siding’s job is to provide a layer of protection for the plaster and bales, keeping rain and other moisture off. If it does it’s job as expected, some small cracks in the exterior wall surface will not be an issue.

I’ll see how the plaster dries today and tomorrow. My thought for Friday is to put windows in on the walls that have the second coat of plaster. The windows which have been stored in the barn for some time will need to be cleaned first. With windows in and the second coat of plaster, the bales ought to be protected well enough from all by a driving rain. I may cover them with plastic anyway until I get a chance to put the siding on. I’ll definitely cover the upstairs walls with plastic before the weekend (maybe we’ll get rain).

It went smoothly. We built the wall on the floor and then raised it into place.

It went smoothly. We built the wall on the floor and then raised it into place.