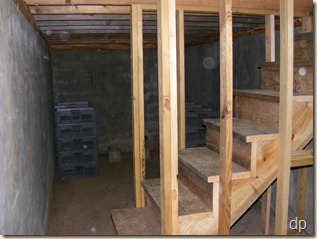

Although I haven’t gotten any more 2x4s yet, I had just enough left to frame the root cellar walls. I’d set some treated 2x4s aside for this purpose, otherwise I’m sure I would’ve used them elsewhere in the house.

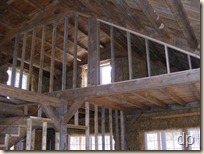

Before framing the cellar walls, I cut the stringers for the stairs into the root cellar. I thought it might be helpful to someone if  I shared the process I used for building the stairs. This is the same method I used for the main stairs in the house (photo at the right).

I shared the process I used for building the stairs. This is the same method I used for the main stairs in the house (photo at the right).

The first thing to do is to figure out the total rise and run for the stairs. For the root cellar, the distance from the concrete floor to the floor above (the first floor of the house in this case) is 90 inches. The root cellar is 96 inches across, but there was extra space above the inner wall of the root cellar, about 12” long and 9 inches to the sill board on the block wall. I wanted to use this for a step, thereby shortening the total length of the stairs. With the total rise and run, I could figure the specific measurement for each step.

The main stairs I built have a 7-1/4” rise and 11” run, which make very comfortable stairs. I knew that I couldn’t build the root cellar stairs to the dimensions. I did not want steps that are too steep – I’ll be using them to haul vegetables/food in and out of the root cellar. I’ve been on some too steep, too narrow, feel-like-you’re-gonna-fall steps before, and I knew I didn’t want that.

I figured if I made the steps have a rise of nine inches, meaning there would be a step up of nine inches for each step, that would come out even (9” x 10 = 90”). In order to figure the run for each step, I computed the total length of the stairs for three different lengths: 9”, 10”, and 11”. With the extra space for a step outside of the root cellar at the top and having a small platform for the bottom step instead of going all the way to the floor, I decided on a 10 inch run for each step. That would be enough space for a foot to comfortably fit.

It was easy to figure the total number of steps I would have to cut into the stringers. The first step would be outside of the root cellar. So the second step would be the first one on the stringers and would be 18 inches below the first floor level, and the stringer would have eight steps (of the ten steps needed, the first one was outside the cellar and the last one was the cellar floor).

The only other consideration was the thickness of the treads and risers. I was using 2x material which is 1.5” thick.  That means for the bottom step, I had to subtract 1.5 inches for the rise to be 9 inches when the tread was put on. And, since I was going to use the cellar wall for the riser on the top step against the wall, I would need to cut it 1.5 inches shorter than the others.

That means for the bottom step, I had to subtract 1.5 inches for the rise to be 9 inches when the tread was put on. And, since I was going to use the cellar wall for the riser on the top step against the wall, I would need to cut it 1.5 inches shorter than the others.

With my figures, I began to lay out the steps. I used a framing square (a handy tool) on which  I clearly marked with pencil the 9” and 10” lines on both sides along the outside edges. By positioning the square on the 2x12 which was to become the stringer with the 9” and 10” marks on the edge, I used a pencil to mark the first step. After the first step, I moved the square so that the 9” mark was at the point where the 10” mark had been which moved the 10” mark further down the edge of the board.

I clearly marked with pencil the 9” and 10” lines on both sides along the outside edges. By positioning the square on the 2x12 which was to become the stringer with the 9” and 10” marks on the edge, I used a pencil to mark the first step. After the first step, I moved the square so that the 9” mark was at the point where the 10” mark had been which moved the 10” mark further down the edge of the board.  I drew the shape and then continued for the rest of the steps.

I drew the shape and then continued for the rest of the steps.

Once the lines were all drawn using the square, I measured the height for the bottom step and the length for the top step (you can keep the height and lengths of the steps straight with the measurements you’ve now transferred to the board – 9 inches and 10 inches). With everything marked, I could begin cutting.

I used my circular saw to cut along the lines, watching carefully so that I didn’t cut beyond the corner –  a round blade will only cut all the way to the corner on the top side. So, once I cut all of them with the circular saw, I finished the cuts with a hand saw.

a round blade will only cut all the way to the corner on the top side. So, once I cut all of them with the circular saw, I finished the cuts with a hand saw.  If there was any unevenness left in the cuts, I cleaned it up with a chisel.

If there was any unevenness left in the cuts, I cleaned it up with a chisel.

Now, I had my first stringer. I could mark the second one the same way, but I opted to use the first one as the template for the second one. I laid it on top, keeping the edges aligned, and marked the treads onto the other 2x12. Then, I cut it the same way as the first one.

The only other materials necessary for the steps were the treads and risers. I had a 2x10 which I cut into 30” lengths for the risers (30” is the width I’d previously decided on for the stairs when framing the floor above the root cellar). They were about 1/4” too wide, so I ripped off the extra on the table saw. For the treads, I used 30” lengths of 2x12s. I did not rip their 11.25” width, leaving 1.25” to hang over on each step.

Before I put the stairs in, I built two short walls to go on either side of the stairs in the root cellar. I nailed them together in the house and then lowered them down into the root cellar.  I convinced them into position (they fit snugly) and secured them with nails into the floor joists at the top and concrete screws into the floor and wall of the root cellar.

I convinced them into position (they fit snugly) and secured them with nails into the floor joists at the top and concrete screws into the floor and wall of the root cellar.

With the walls in place, I situated the stringers and nailed them to the wall studs. Then, it was a matter of nailing on the risers and the treads. I had to figure out and build the top step on its own (no riser) and extend the bottom step for a short platform.

The length of the walls provides for 30 inch openings at either side of the steps at the bottom. The right section of the root cellar will be the larger of the two rooms. We haven’t decided exactly how we will store things, but given time we will. If the smaller room on the left can be kept a little warmer, it would be a nice place for storing sweet potatoes, onions, garlic, winter squash – the things that like it a little bit warmer and not too damp.